Where quality calls home.

Kurt Minneapolis, MN Machining Division Quality Management System Registrations:

- ISO 9001:2015 + AS9100D

- ITAR Registered

- Smart -Profile Dimensional Analysis Software

- Net-Inspect Quality Improvement Software

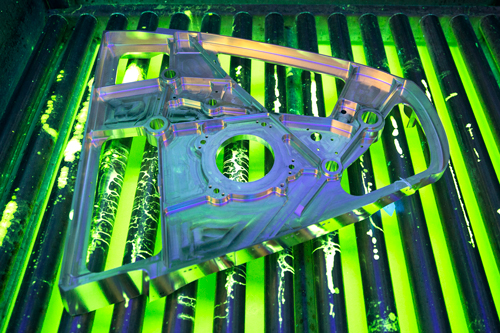

- NADCAP Certified — Non-Destructive Testing (NDT)

- NADCAP Certified — Chemical Processing

- MIL-Q-9858 or MIL-I-45208

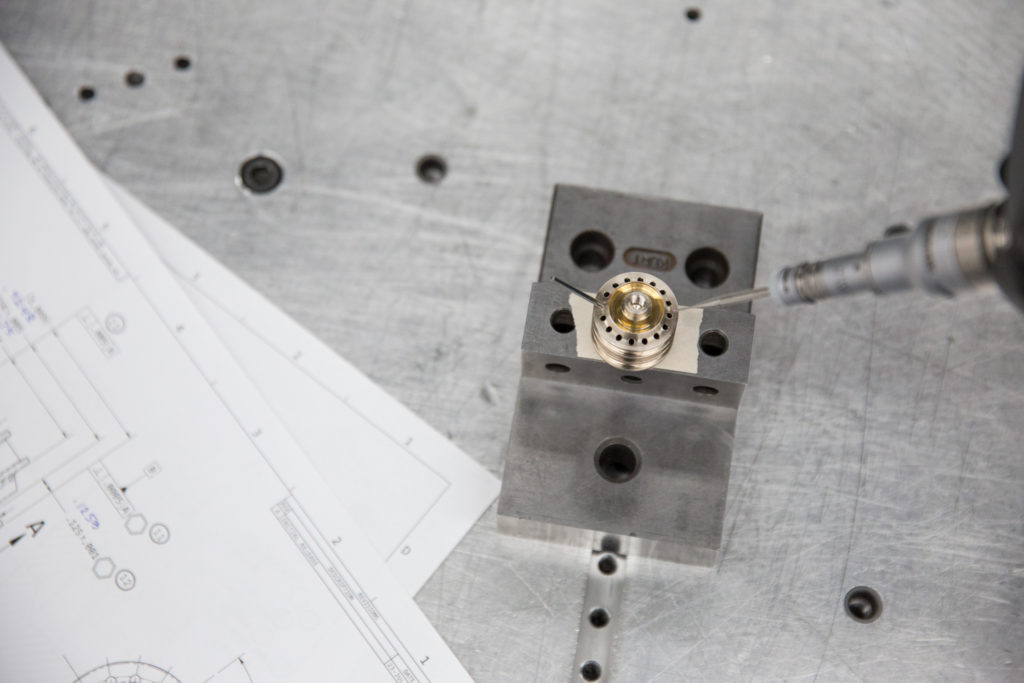

Quality Equipment Highlights

At Kurt Machining, customers get access to our state of the art quality department with some of the most advanced CMM’s Available

2 Brown and Sharp Global Advantage

- 47.2″ x 118.1″ x 39.4″

- PC-DMIS CAD ++ Software

- Top acceleration up to 4.3m/s2

- Volumetric accuracy to 8 Microns

1 Brown and Sharp Global S

- EPS (Enhanced Productivity Series)

- 47.2″ x 118.1″ x 39.4″

- PC-DMIS CAD ++ Software

- Top acceleration up to 4.3m/s2

- Volumetric accuracy to 8 Microns

1 Brown and Sharp Global Advantage

- 47.2″ x 86.6″ x 39.4″

- PC-DMIS CAD ++ Software

- Top acceleration up to 4.3m/s2

- Volumetric accuracy to 8 Microns

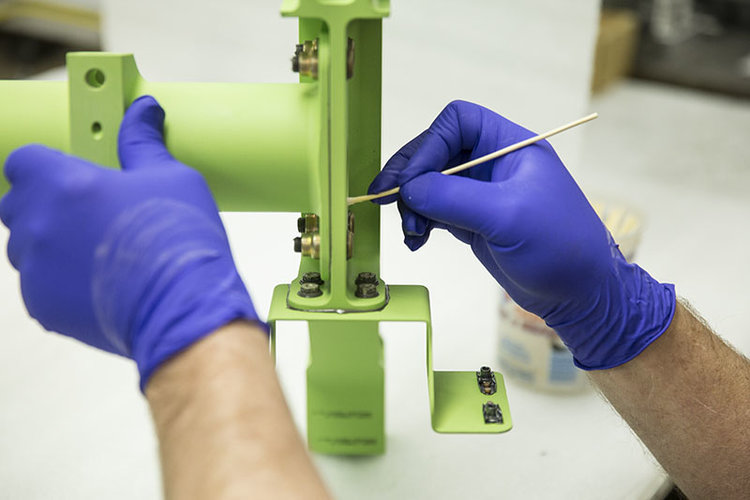

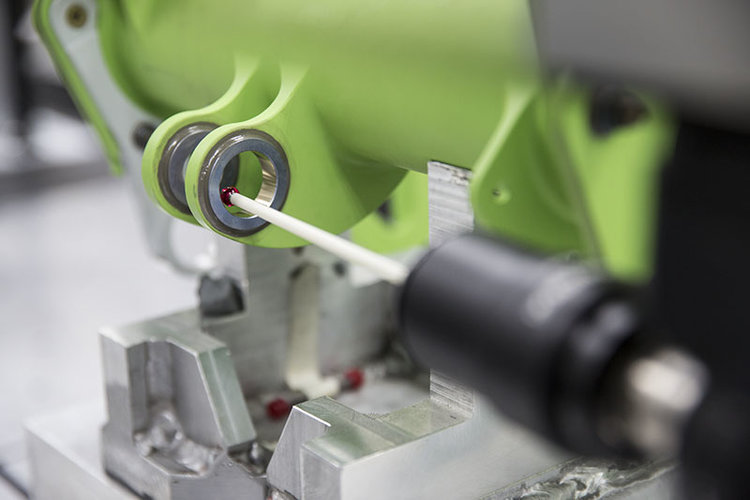

Our customers care about getting quality parts, delivered on time. To ensure customers receive this exceptional experience, Kurt Manufacturing utilizes Lean Manufacturing Methods, program management and MRP II system with scheduling, inventory and production control systems. Kurt also incorporates added controls in current quality systems and internal finishing processes to meet or exceed our customer expectations. Through Kurt state-of-the-art robotics and automation in our manufacturing line, we are able to gain precision and improve quality.